Several additive packages are introduced into rubbers to vary the chemical and physical properties of the polymer. The qualitative and quantitative analysis of these additives requires sample pretreatment, such as solvent extraction, to isolate or concentrate the additives of interest. For example, when analyzing Styrene-Butadiene Rubber (SBR) for the total amount of fatty acids, the sample is first extracted using ethanol/toluene followed by titration; however, this method requires large amounts of solvent, excessive analyst time, and can be prone to contamination as well as other errors. The result of this additional sample handling reduces laboratory productivity and information obtained exhibits poor precision and accuracy.

In response to these analytical challenges, Reactive Pyrolysis-GC/MS (RxPy) with TMAH (Tetramethylammonium hydroxide) method was developed using the Frontier multi-shot pyrolyzer. This study will demonstrate the efficacy and viability of the Frontier reactive pyrolysis GC/MS analysis of a vulcanized SBR sample using TMAH for rapid and straightforward determination of free fatty acids. Free fatty acids contained in a vulcanized rubber product will be determined as methyl derivatives by Thermally Assisted Hydrolysis and Methylation-GC/MS with no need for sample pretreatment, such as solvent extraction.

Reactive Pyrolysis GCMS technique offers producers solutions to eliminate solvent extraction and gain quality control efficiency while enhancing precision in quantitative analysis

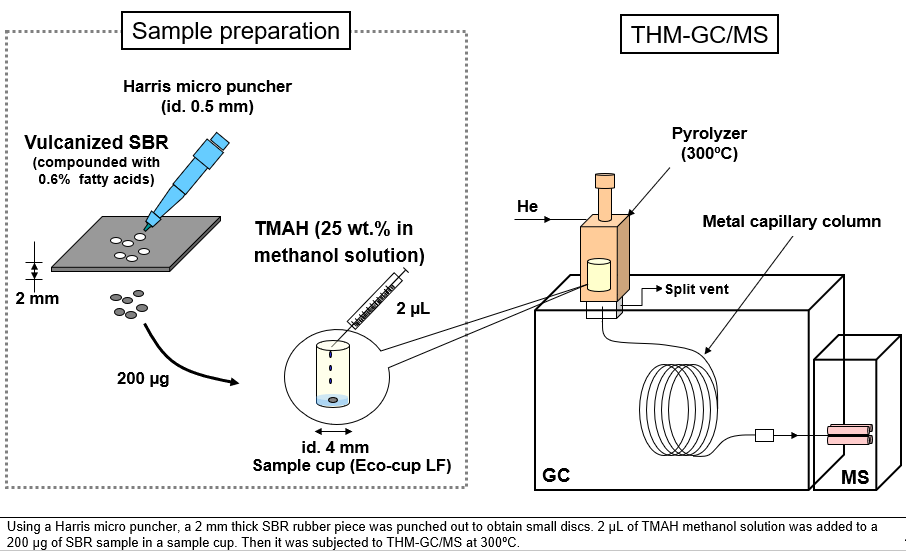

Experimental: An SBR rubber sample was analyzed using the Frontier Multi-Shot Pyrolyzer (EGA/PY-3030D) directly interfaced to the injection port of a GC/MS. A Micro Puncher (2 mm, Frontier Labs) was used to cut a plug of the sample (200 µg) which was placed in a sample cup. Next, two µL of 25 wt% TMAH was added to the cup and the cup was placed in the Auto-Shot carousel (shown in figure 1). The analysis was automated using an Auto-Shot Sampler (AS-1020E, Frontier Labs).

Figure 1. Sample Preparation and instrument configuration

The sample cup was subsequently dropped into the hot zone (300⁰C) of the quartz liner. The derivatized fatty acids were swept through the GC splitter and sent to the separation column. The separation column was an Ultra ALLOY-5 metal capillary column.

Note: Using EGA (Evolved Gas Analysis) elution peaks for free fatty acids (stearic acid and palmitic acid) were observed in the range between 150ºC and 300ºC. Based on this observation, the optimal thermal desorption temperature for THM-GC/MS analysis was determined.

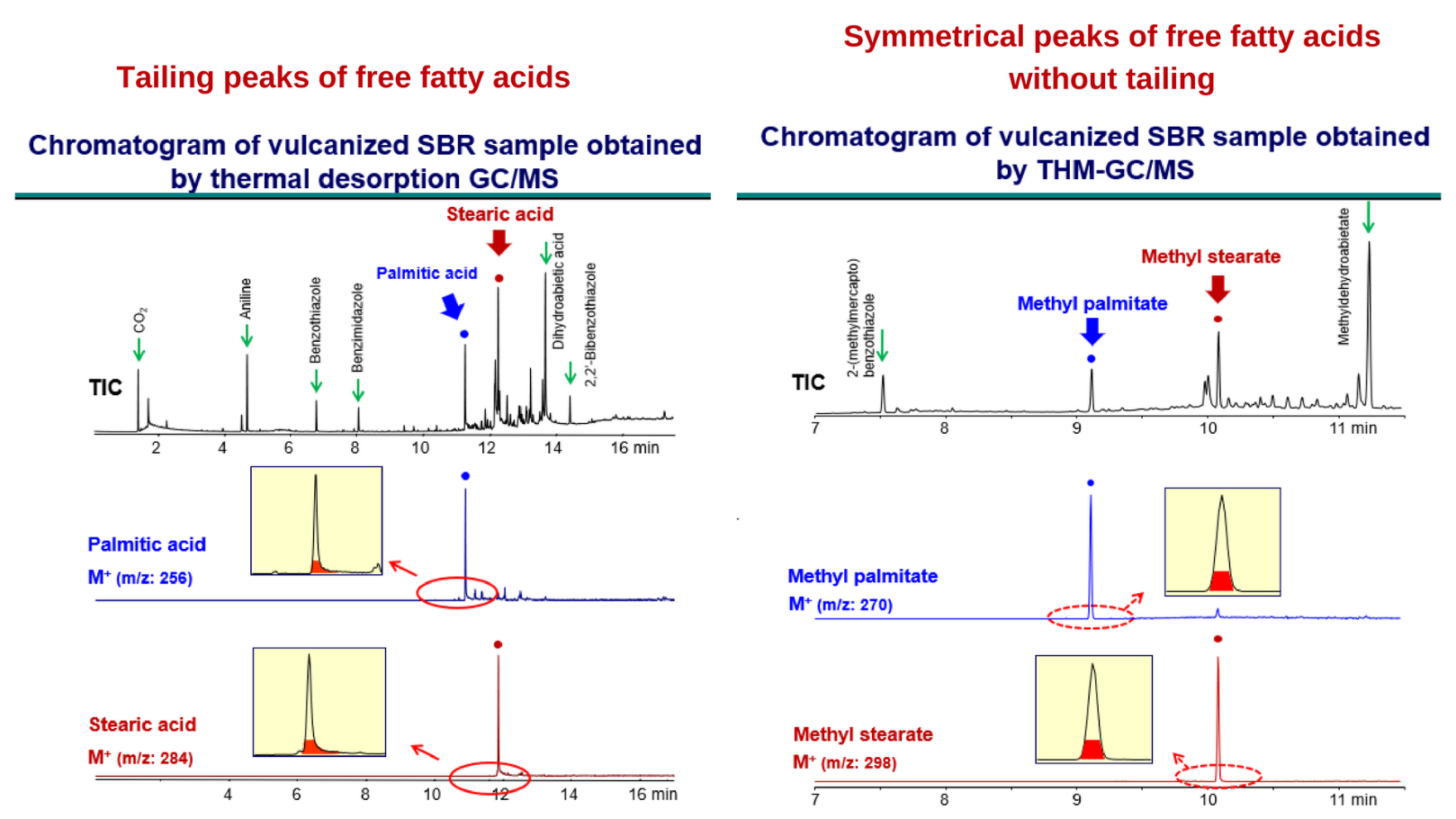

The total ion chromatogram of the products formed using reactive pyrolysis have peaks for the methyl esters of palmitic (C16:0) and stearic acid (C18:0). No peak tailing is observed in the extracted ion chromatograms of the M+ ions compared to tailing peaks of the free acids when reactive pyrolysis is not performed (shown in figure 2). Peak tailing can lead to poor quantitation results.

Figure 2. Thermal Desorption GC/MS Versus THM-GC/MS (Reactive Pyrolysis GC/MS)

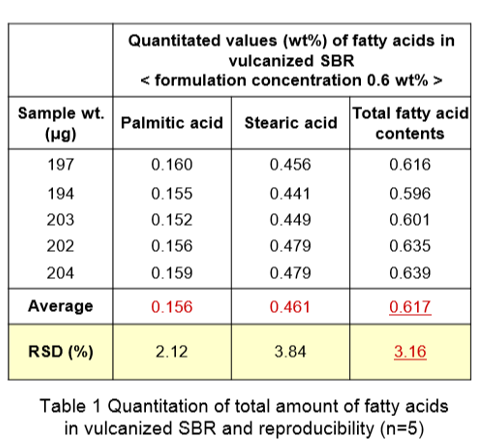

The concentration of each acid was determined to be 0.16 wt% (C16:0) and 0.46 wt% (C18:0) using the peak area of the M+ ions and a single point external standard calibration. Total fatty acid concentration is 0.62 wt% which is in good agreement with the original formulation concentration of 0.6 wt%. The precision (n=5) of the individual fatty acids determinations is 2.1%RSD and 3.8%RSD (shown in table 1).

Conclusion: Today, more laboratories in the rubber, polymer, and automotive industries are integrating the Frontier multi-shot pyrolyzer into their mainstream analytical protocols due to the advantages and immediate quality improvements this technique provides. In fact, reactive pyrolysis is a simple and highly reliable analytical method which requires no pretreatment, such as solvent extraction. Eliminating the solvent extraction process before the analysis, enhancing precision in quantitative analysis, and improving efficiency in the operation are some of the primary reasons many manufacturing and polymer maker laboratories in the automotive industry are utilizing the Frontier Pyrolyzer.

You can download our Automotive Application E-Booklet Here!

This technical note is the shortened version of the study. You can request the full technical application note/booklet as well as the technical information about the Multi-Shot Pyrolyzer and its capabilities by contacting us at no cost and commitment.

References: ATSUSHI WATANABE, CHUICHI WATANABE1, HAJIME OHTANI2

- Frontier Laboratories Ltd., Koriyama, Fukushima 963-8862, Japan

- Nagoya Institute of Technology, Nagoya 466-8555, Japan