Today, more laboratories are integrating the Frontier Multi-Shot Pyrolyzer into their mainstream analytical protocols due to the advantages and immediate quality improvements this technique provides. In addition to the reliability, accuracy, precision, automation, and reproducibility of this technique, Pyrolysis GCMS has several advantages over a regular GCMS system.

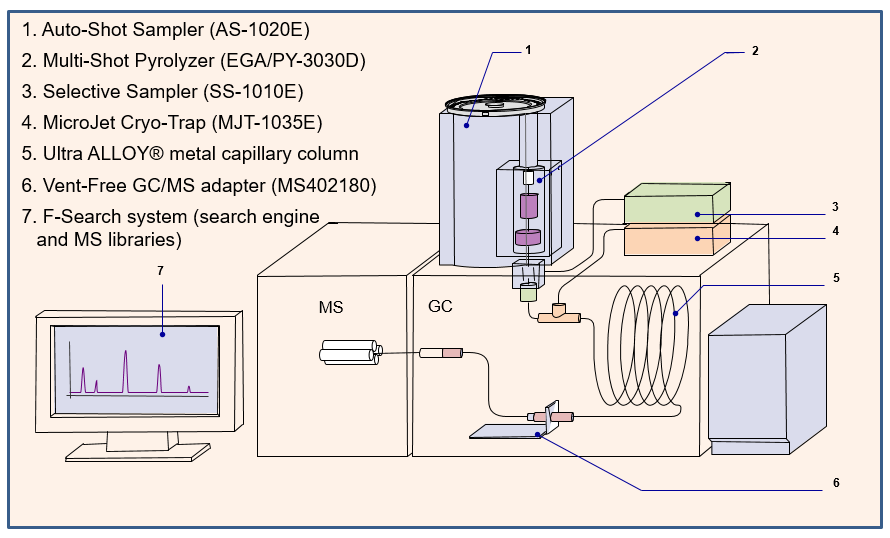

As we all know, a GCMS system can be used only for material characterization of liquid or gas samples while the maximum GC inlet temperature is around 320°C. In addition, a GCMS system is typically limited to organics that vaporize at < 320°C. Only a single analysis can be performed for each sample injection with this technique. On the other hand, the mix of Pyrolysis with GCMS techniques allow new capabilities for analysis of otherwise intractable samples by GCMS. This powerful technology is comprised of a Frontier Multi-Shot Pyrolyzer coupled with a GCMS system to enhance the capabilities of a GCMS system (shown in figure 1 below).

Using Pyrolysis GCMS, solid samples can be analyzed in addition to liquids and gases. In fact, there is no solvent required when using Pyrolysis GCMS as opposed to GCMS technique. In other words, the solid and liquid samples can be injected into the Pyrolyzer without any solvent and sample pretreatment like solvent extraction! This advantage is one of the primary reasons many laboratories are integrating the Frontier Pyrolyzer into their day to day and research analytical protocols. Think about the amount of money this capability will save your laboratory over time. In addition to eliminating solvent costs, these laboratories are protecting their scientists from solvent exposure while operating environmentally friendly.

Pyrolysis GCMS techniques also enables material characterization of virtually any organic material by providing detailed information about the composition of the samples. This technique is used for identification of complex polymers, copolymers, volatiles, and additives as well as failure, contamination, deformulation, and degradation analyses. As opposed to GCMS, Pyrolysis GCMS allows multiple and customized analysis on the same sample while the MS libraries offer a broad range of references: from low b.p. compounds to pyrolyzates and heavier polymeric fragmentations. In terms of the ability to run samples at higher temperature, the Frontier Multi-Shot Pyrolyzer provides the user with an expanded temperature range from ambient + 10 to 1050°C (± 0.1°C precision) as well as a high Interface temperature (maximum 450°C).

Now that you read about the advantages and new capabilities that Pyrolysis GCMS brings your laboratory, you may ask how a difficult polymer or solid sample is breaking down with the Pyrolysis GCMS technique. How can it be ensured that the sample is not over heated? Your question is very valid and Frontier has an answer based on its proven well-engineered technology. As mentioned, the Frontier Multi-Shot Pyrolyzer allows multiple analyses on a same sample. One of these analyses is Evolved Gas Analysis (EGA) which provides the user with a clear picture of the unknowns’ composition by identifying the thermal zones and the compounds in each zone. In other words, EGA thermogram of a sample determines the accurate temperature zones for identifying the composition present in the sample. In fact, a sufficient amount of heat is programmed into the sample via the precisely heated Pyrolyzer to obtain the information of interest about each sample. Therefore, there is NO overheating and/or underheating of the sample!

To learn more about the Frontier Multi-Shot Pyrolyzer and how this technique can add value to your laboratory connect with us today. Simply request technical notes at no cost related to your analytical work and industry.

Figure 1. Pyrolysis GCMS Configuration

Figure 1. Pyrolysis GCMS Configuration