Thermal Desorption-GC/MS is a powerful and straightforward technique that utilizes a Frontier micro-furnace technology pyrolyzer as a programmable temperature inlet to a Gas Chromatography-Mass Spectrometer (GC/MS) system. The material of interest is uniformly heated in an inert atmosphere. Volatile organics evolve at temperatures below 300 °C. At higher temperatures, covalent bonds break and the complex structure is degraded into smaller (stable and volatile) molecules which are referred to as pyrolyzates. The pyrolyzates formed and their relative intensities provide insight into the structure of the original material.

The Frontier Pyrolyzer is interfaced directly with the GC inlet (no transfer line). The sample is placed in a small inert cup which is, in turn, positioned in a micro-furnace. The temperature of the sample is precisely controlled (±0.1 °C) to ensure that the sample-to-sample thermal profile is identical. The micro-furnace technology protects the sample at ambient temperature, in an inert atmosphere, prior to analysis; thus eliminating evaporation, thermal degradation, and thermosetting before analysis.

Using the multi-mode micro-furnace pyrolyzer multiple analytical techniques can be performed: Evolved Gas Analysis (EGA), Thermal Desorption (TD), true Flash Pyrolysis (PY), Double-Shot (TD followed by PY), Heart-cutting (HC), and Reactive Pyrolysis (RxPy).

In this brief technical note, the TD mode of operation of the multi-mode pyrolyzer is used for analyzing the flavor components of the red wine. The analysis is performed using a solid-phase extraction (SPE) Magic Chemisorber® (chemically bonded PDMS layer on titanium tube). The Chemisorber is used for analyzing the trace amount of organics in the air or aqueous solutions and for headspace analysis of solids or solutions. It is placed in a sample (gas, aqueous solution, or solid) for a fixed period, the extracted components are then analyzed by the multi-mode pyrolyzer in the TD mode of operation.

Experimental: Magic Chemisorber® MC-S500 (PDMS thickness 500 µm) was immersed in 10 mL of a domestic red wine for 30 min at 22ºC. Then, the surface of the Chemisorber was cleaned using KimWipes before the analysis. The Magic Chemisorber® was placed in a flow-through Eco-cup LHF and heated to 250ºC for 15 min using the multi-mode pyrolyzer. Thermally desorbed compounds were swept by a carrier gas to the GC injection port configured for splitless operation. The desorbed compounds were once cryo-trapped at the head of the separation column using a MicroJet Cryo-Trap, and then they were sent to the separation column and detected by a quadrupole MS detector.

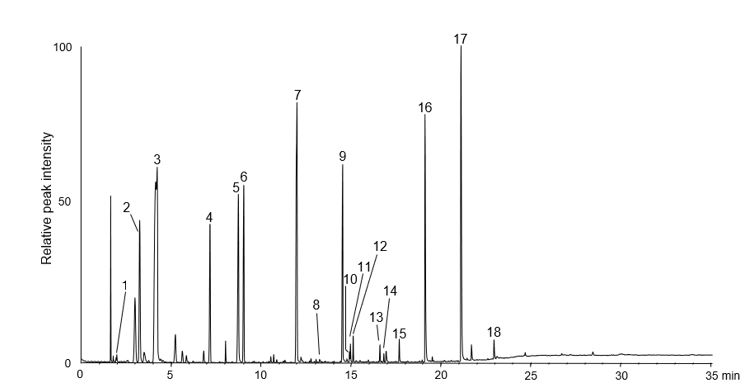

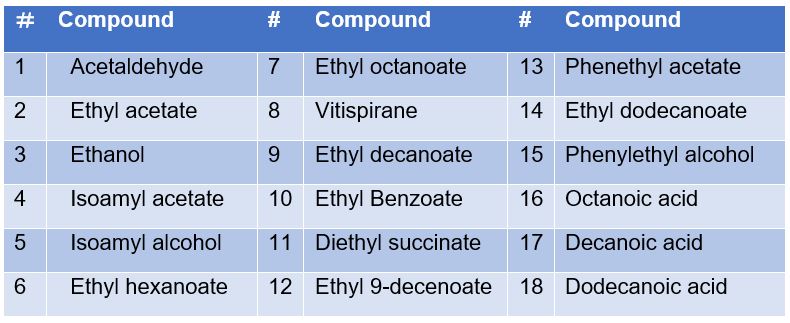

Results: A chromatogram of the extracted compounds from the red wine is shown in Fig. 1, and peak assignments are summarized in Table 1. Various components contained in the red wine were observed, including ethyl octanoate and decanoic acid. The results show that the use of the Magic Chemisorber® and the pyrolyzer configured for thermal desorption is a quick and simple technique for analyzing flavor components in liquid samples. The TD mode of operation can be used in both isothermal and temperature-programmed methods.

Fig. 1 Chromatogram of extracted compounds from red wine by Magic Chemisorber

Table 1 Components extracted from red wine

To learn more about the multi-mode micro-furnace pyrolyzer, its modes of operations, and what is it about this technology that gives you superior results, visit us at www.frontier-lab.com or simply connect with us.

References:

L. Wang et al., J. Chromatogr. A 1035 (2004) 277-279.

Frontier Laboratories Ltd. 4-16-20 Saikon, Koriyama, Fukushima, 963-8862 JAPAN