Recycling of plastic wastes is an increasing social concern as a method of reducing negative environmental impact and resource depletion. During the reprocessing of plastic wastes, the recycled plastics may be contaminated by originally formulated additives such as brominated flame retardants (BFRs) that are restricted by the RoHS Directive.

Most of the traditional methodologies for the determination of BFRs are based on solvent extraction, filtration, and concentration. These techniques are cumbersome, time-consuming, and suffer from analyst-to-analyst variability while producing data of limited value.

On the other hand, Thermal Desorption-Gas Chromatography/Mass Spectrometry (TD-GC/MS) does not require any of the traditional solvent extraction or sample pretreatment. Milligram quantities are put in an inert sample cup which is then ‘ready to analyze’. This technique is performed by the multi-mode Pyrolyzer with a vertical micro-furnace technology that allows programmable and multiple thermal desorption analysis on a single sample.

The Multi-Mode Pyrolyzer provides users with multiple modes of operations and techniques: Evolved Gas Analysis (EGA), Thermal Desorption (TD), flash Pyrolysis, Heart-Cut (thermal slicing), and Reactive Pyrolysis. EGA is the first step in material characterization providing a clear picture of the thermal profile for the sample.

Experimental: In this brief technical note, waste plastic foam is analyzed by TD-GC/MS to detect BFRs. The thermal desorption temperature zone is identified using EGA thermogram. The analysis is performed using the Multi-Shot Micro-Furnace Pyrolyzer (EGA/PY-3030D) that is directly interfaced to the GC injector. The sample was cut into thin slices which were placed in a sample cup. The sample cup was free-fallen into the furnace and subsequently heated to 350ºC. The thermally desorbed components were once cryo-trapped by a MicroJet Cryo-Trap at the head of a separation column, then sent to the separation column by a He carrier gas and detected by the mass spectrometer.

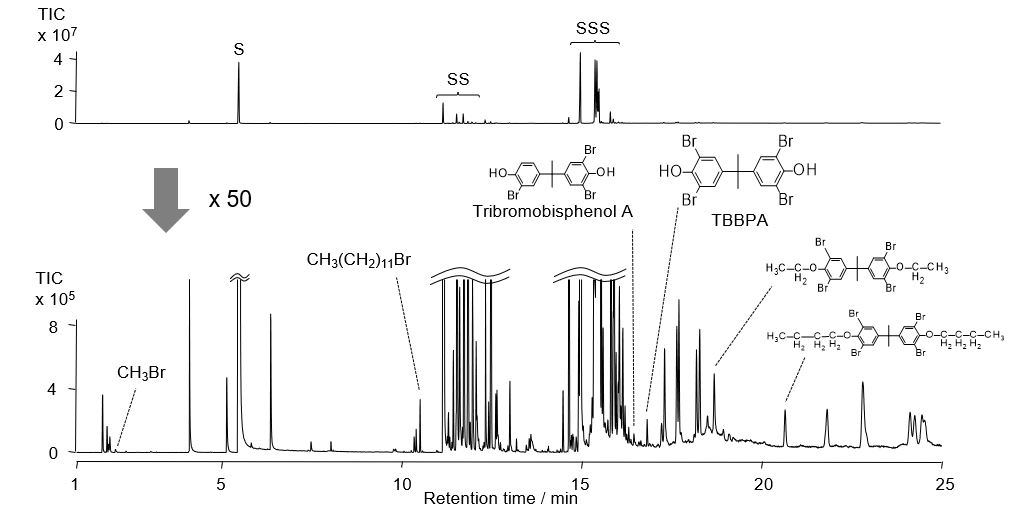

Results: A TD chromatogram of the sample and the 50-fold expanded chromatogram are shown in Fig.1. Peaks for styrene oligomers were easily recognized. Also, six brominated compounds, including tetrabromobisphenol A (TBBPA), a general-purpose BFR, were observed. In addition, various brominated compounds, that were formed during the TD process or recycling process of the waste plastic containing BFRs, were observed. The quantitative analysis of TBBPA contained in the sample can also be performed (Click Here to read part 2 of this technical note for quantitative analysis of TBBPA).

Pyrolyzer furnace temp.: 177 – 350ºC (2 min hold, 70 ºC/min), Separation column: UA+-5 (5% diphenyl 95% dimethylpolysiloxane, L=30 m, i.d.=0.25 mm, df=0.25 μm), Column flow rate: 1 mL/min (He), Split ratio: 1/20, GC oven temp.: 40 (2 min) – 320ºC (10 min hold, 20 ºC/min), Sample amount: ca.1 mg, Thermally desorbed components were cryo-trapped using MicroJet Cryo-Trap. S, SS, and SSS represent monomer, dimer, and trimer of styrene, respectively.

Using Thermal Desorption GC/MS, solid samples can be analyzed. There is no solvent required as opposed to traditional GC/MS techniques. In other words, the solid and liquid samples can be injected (using an inert sample cup) into the Pyrolyzer without any solvent and sample pretreatment. This advantage, as well as rapid screening capability, is one of the primary reasons many laboratories integrate the multi-mode Frontier Pyrolyzer into both their day-to-day QC and analytical research protocols.

To learn more about Frontier multi-mode pyrolyzer, its operation modes, and what is it about the micro-furnace technology that gives you superior results, visit our website or simply connect with us.

Reference: Frontier Laboratories Ltd. 4-16-20 Saikon, Koriyama, Fukushima, 963-8862 JAPAN