There are various types of Pressure Sensitive Adhesives (PSH) such as silicones, polyurethanes, acrylics, and rubbers. Acrylic adhesives have different applications in many industries such as electronics, medical, consumer goods, and product labors. Often the chemical composition of these acrylic adhesives is not disclosed. Deformulation and contamination analysis on these adhesives are key analytical protocols for many testing laboratories to ensure the products comply with quality control on physical property and performance.

In this brief technical note, deformulation analysis is performed on a commercial dicing tape using the EGA/PY-3030D multi-mode pyrolyzer. The dicing tape sample is used for semiconductor manufacturing processes. In the dicing process, a silicon wafer layer that is bonded to the adhesive is cut into pieces with a dicing saw. Using UV light, the adhesive is crosslinked and cured to reduce the adhesive strength of the tape. By reducing the adhesive strength, the wafer chip is easily detached from the tape.

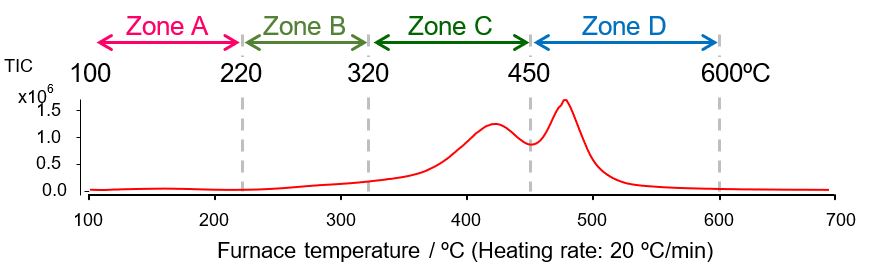

Experimental: The first step in performing the deformulation analysis is Evolved Gas Analysis (EGA). EGA is one of the modes of operation using the multi-mode pyrolyzer. In this mode, the Pyrolyzer’s furnace is programmed from 100 to 700°C (20°C/min). As the furnace’s temperature is increasing, the gases evolve from the sample and transferred into the MS for identification. Figure 1 shows the EGA thermogram obtained from the commercial dicing tape. EGA is a rapid screening technique that provides a clear picture of the thermal profile of a sample.

Figure 1. EGA Thermogram of the Commercial Dicing Tape Sample

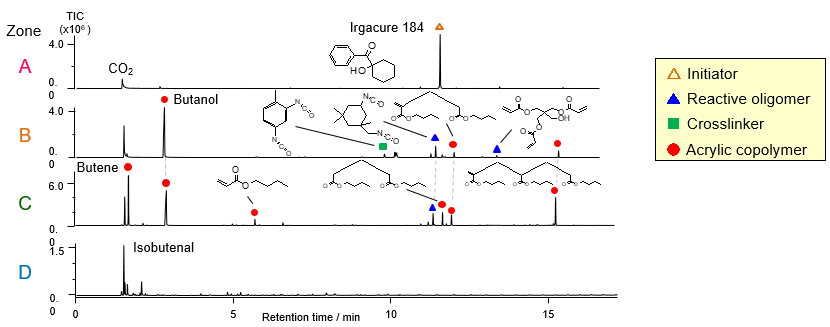

As shown in Figure 1, the EGA thermogram can be sliced into 4 temperature zones. Each temperature zone can be analyzed using the heart cut (HC)-MS mode of the pyrolyzer. In this mode, the pyrolyzer’s furnace is programmed from 100 to 220°C, 220 to 320°C, 320 to 450°C, and then 450 to 600°C. In fact, 4 analysis is performed on one single sample of the dicing tape while 4 separate GC/MS chromatograms are obtained (shown in Figure 2). The peaks for each zone are identified using F-search interpretation libraries.

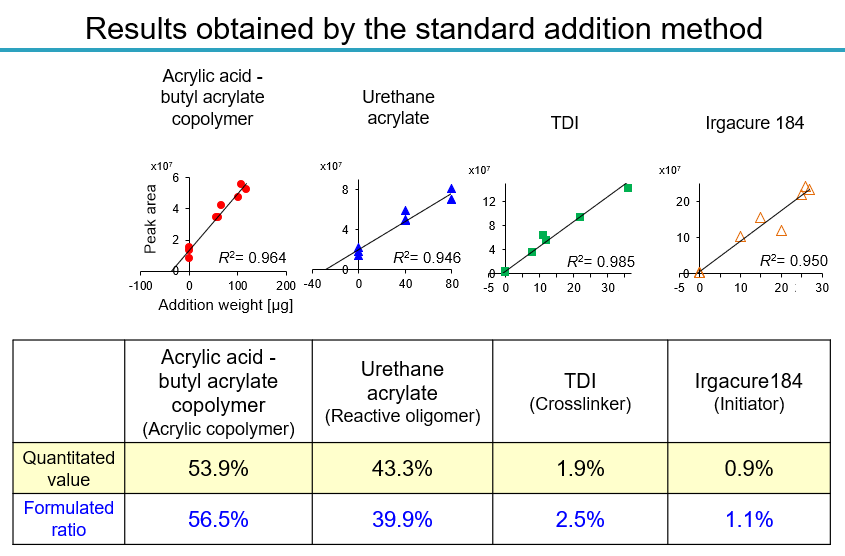

Using the standard addition method, the calibration curve for each category (initiator, reactive oligomer, crosslinker, acrylic copolymer) were obtained to calculate the quantitated values for comparison with the formulated values.

Conclusion: Adhesives used in a dicing tape were analyzed by HC/EGA-GC/MS in combination with the F-Search system. The components related to the acrylic adhesive, such as acrylic copolymer, crosslinker, reactive oligomer, and initiator, were easily identified. The formulation of the dicing tape adhesive were also determined quantitatively by Py-GC/MS using the standard addition method. The results agreed well with the original manufacturer formulation.

It is important to note that performing flash pyrolysis alone can generate ambiguity in the results. However, the addition of EGA and Heart-Cutting results clearly indicated components that arise from the polymer versus components that are present as small molecules or volatile components in the formulation.

Using PY-GC/MS solid samples can be analyzed directly; no solvent is required as opposed to traditional GC/MS techniques. In other words, the solid and liquid samples can be injected (using an inert sample cup) into the Pyrolyzer without any solvent and sample pretreatment.