Organic pigments are widely used in paint and ink formulations. The analysis and structure elucidation of organic pigments are challenging because they are not only insoluble in organic solvents but also many of them have similar structures. All the past methodologies for determination of organic pigments are based on solvent extraction, filtration and concentration. These traditional techniques are cumbersome, time consuming, and suffer from analyst-to-analyst variability while producing data of limited value.

Solving Analytical Challenges is the Driving Force at Frontier Lab

Frontier Py-GC/MS offers a revolutionary solution for analyzing organic pigments in a complex matrix in the paint, ink, and coating industry. Samples are analyzed directly; no pretreatment such as solvent extraction is necessary. Pyrolyzates are separated on a high-resolution capillary column and identified using both spectral (MS) and retention (GC) data. This technique can be used both qualitatively and quantitatively and allows multiple and customized analysis on each sample. While the Frontier Pyrolyzer has a variety of applications in the paint and coating industry, this short technical note demonstrates some of the advantages this technique can offer to analytical laboratories for enhancing efficiency, data quality, and quality assurance.

Experimental

In this work, the Frontier Py-GC/MS analysis was used for analyzing relatively large-molecular-weight (MW approx. 1,000) nonvolatile pigments including condensation disazo pigments having similar structures, azo lake pigments, and phthalo-cyanine pigments.

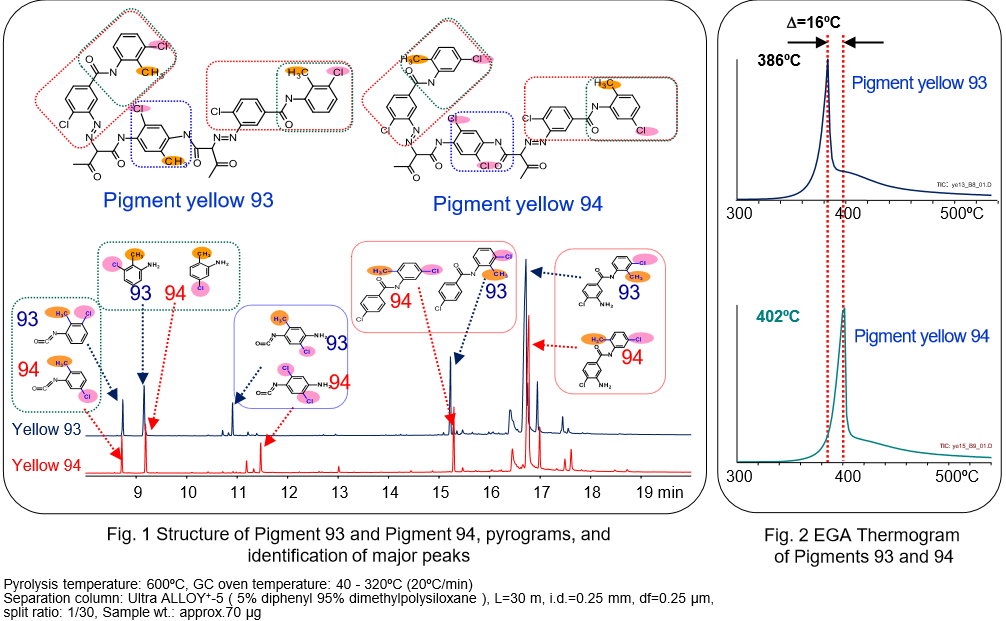

The first step in characterizing the organic pigments was the Evolved Gas Analysis (EGA) technique. EGA provides a “picture” of the sample’s complexity. In this technique, the sample is dropped into the furnace which is at a relatively low temperature. The furnace is then programmed to a much higher temperature. Compounds “evolve” from the sample as the temperature increases and then a plot of detector response versus furnace temperature is obtained. In this study, The EGA-MS was performed by programming the furnace 100→600⁰C at 20⁰C/min.

The second step was to analyze the thermal zones of interest obtained from EGA thermograms. Pyrolysis-GC/MS at 600ºC were performed on 35 organic pigments using Py-GC/MS. Using F-Search (Frontier’s patented search engine with 4 unique libraries) an organic pigment library was created and used to process the MS sample data. The spectral information from the Py-GC/MS analysis was incorporated into the searchable MS library using Frontier’s F-Search engine.

Additional organic pigments can easily be added. Such a “pigment” library can be used to identify pigments in an ‘unknown’ sample.

Results and Discussions

The results obtained by the EGA-MS and Py-GC/MS analysis of Pigment yellow 93 and Pigment yellow 94 are shown below. The molecular structures of these two pigments have similar structures. This data was used to construct a database to identify unknown pigments which have similar structures. When analyzing samples containing multiple pigments, the Py-GC/MS is extremely useful since the pyrolyzates of each pigment can be separated, identified, and quantitated. The detail information provided by this technique (compound’s name, structure, and Molecular Weight) along with there being no sample preparation and solvents required makes PY-GCMS a promising analytical tool in this industry to make those difficult challenges simple.

Utilizing Frontier Pyrolyzer to Drive Data Quality and Efficiency

Today, more laboratories are integrating the Frontier Multi-Shot Pyrolyzer into their mainstream analytical protocols due to the advantages and immediate quality improvements this technique provides. Virtually any material (gas, liquid or solid) can be chemically characterized using this technique. The Frontier Multi-Shot Pyrolyzer Guarantees reproducibility and accuracy because every facet of the system is designed to ensure reliability and data quality. All surfaces in contact with the sample are quartz or deactivated stainless steel. There is NO transfer line and NO cross contamination! The system also increases laboratory productivity as sample preparation takes less than five minutes, and the low mass ceramic furnace heats and cools in record time for efficient and continuous sample analysis. This technique requires a small amount of sample which reduces the cost of sample shipping, handling, and disposal. In addition, NO solvent is required when analyzing a sample.

Conclusions

Frontier Pyrolyzer coupled with a GCMS:

- Enables material characterization of virtually any organics by providing detail information about the composition of the samples.

- Provides the users with a clear picture of the unknowns’ composition and the method map by identifying the thermal zones and the compounds in each zone.

- Analyzes solid and liquid samples without any solvent and sample pretreatment like solvent extraction. Laboratories with this capability can eliminate solvent costs and protect their scientists from solvent exposure while operating environmentally friendly.

- Allows multiple and customized analysis on the same sample while increasing the laboratory productivity as sample preparation takes less than five minutes, and the low mass ceramic furnace heats and cools in record time for efficient and continuous sample analysis.

There are several other technical applications in the paint and coating industry using this technique. To find out how Frontier Pyrolyzer can add value to your laboratory and quality control measurements, request additional technical notes and product information at no cost. We look forward to hearing from you and solving your analytical challenge!